Raw materials

Raw materials are carefully selected and tracked.

In its workshop, SNAC manufactures plain rubber pads and steel reinforced rubber pads with or without sliding surface, non-slipping element, anchors, steel restraints, all elements for a suitable bearing with the structure.

Raw materials are carefully selected and tracked.

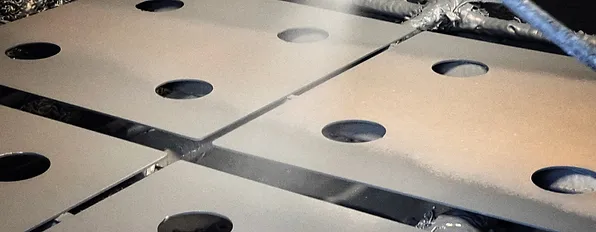

An accurate and parfait cut.

Sandblasting of the steel for the best adhesion.

Rogorous coating process

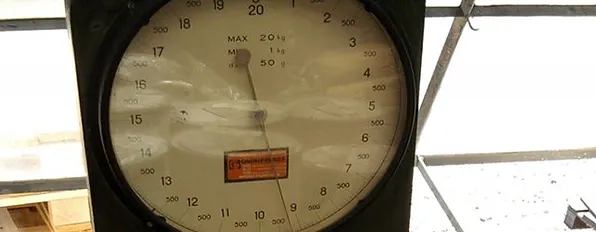

Weighing of all composants during assemblying

Rubber mixing

Each rubber layer is accurately calendered.

Rubber layer are cut at required plan dimensions

Rubber and steel layers are manually assemblyed

Assembled layers are vulcanized at high temperature and pressure in a mould.

All pads are visually controlled and samples are regulary tested in our laboratory.

SNAC attaches a great importance to the delivery time of its products.

SNAC has its own laboratory to control to maintain the best quality of its products. Tests according to norms and quality documents can be given as per customer request.

Material certiticates and conducted tests:

– G Shear modulus

– Compression stiffness

– Repeted compression tests

– Static rotation capacity

– Shear bonding resistance

– Rubber certificate characteristics

– Steel certificate

+33 (0)2 33 39 72 65

[email protected]

6, Rue des Rainettes 61150 RANES

Monday – Thrusday

8am/12pm

1:30pm/5:30pm

Friday

8am/12pm

Tous droits réservés groupe R.C.A.